Our Amazing Clients

These are just a few of the amazing companies that have already implemented REWO.

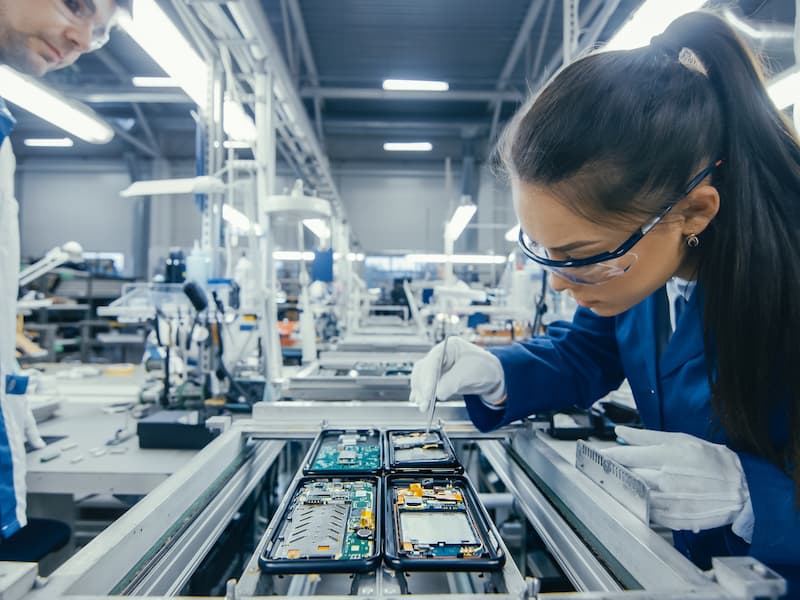

How companies use REWO?

Discover how REWO is helping companies achieve operational excellence.

What others say about REWO?

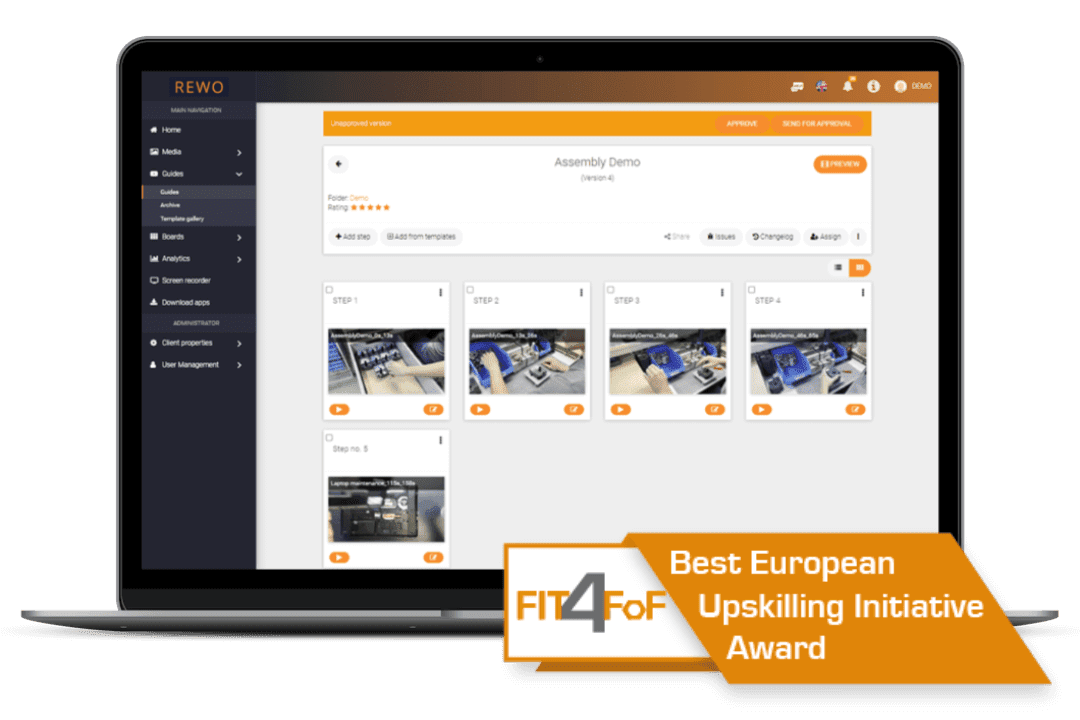

Why should you use REWO?

Production Continuity

Document your work processes in a way that better prepares you for any current or future production disruptions.

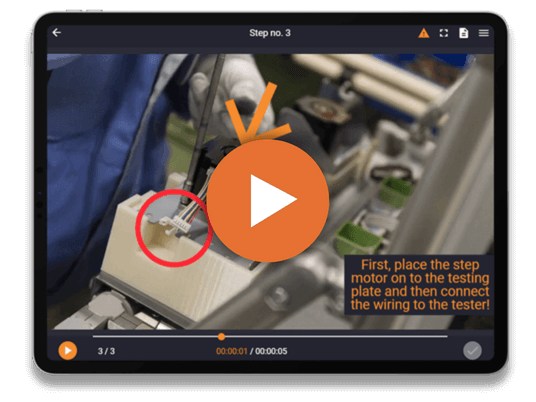

Continuous Learning

Turn training into continuous learning by creating visual lessons and instructions that workers like to watch.

Remove Inconsistencies

By visualizing your work instructions you will improve your company’s performance and remove inconsistencies.

Efficient Onboarding

Improve your training effectiveness and at the same time reduce your training costs when adding new people to your workforce.

Impress Your Partners

By going beyond how companies are documenting their processes today you will improve your company’s reputation and image.

Knowledge Safekeeping

With our efficient documentation process and flexible deployment options your know-how will be kept safe for generations to come.

Unsure where to start? Don’t worry! Our Ultimate Guide to Creating Effective Work Instructions for Manufacturing is the perfect place to begin. This comprehensive guide walks you through the best practices, tips, and strategies for creating clear and impactful work instructions that improve efficiency and reduce errors.