How to get started with Industry 4.0?

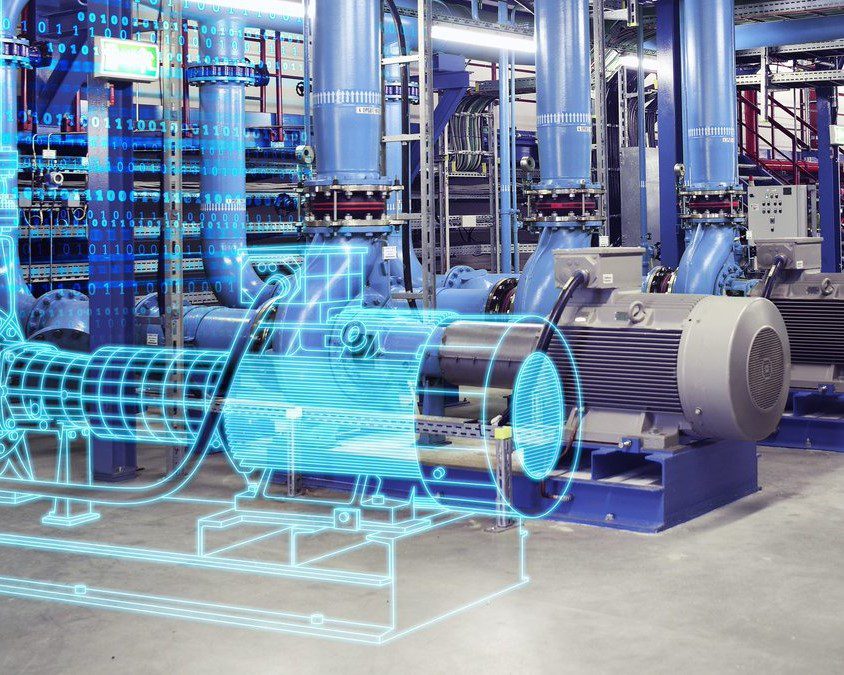

Manufacturing has traditionally been considered to be a process that turns raw materials into physical products. Nowadays, the production phase is only a small part of a much wider value chain which is becoming increasingly interconnected. Manufacturers eager to reap the benefits of Industry 4.0, including greater visibility and control, cost savings and more efficient […]

How to get started with Industry 4.0? Read More