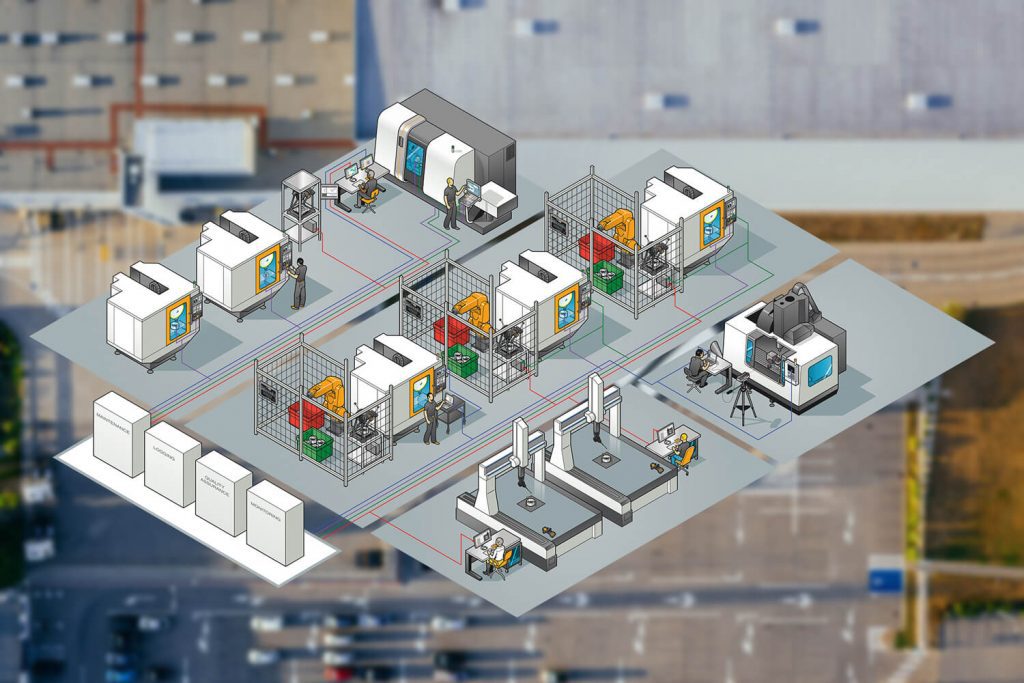

The smart factory is a flexible system that can self-optimize performance across a broader network, self-adapt to and learn from new conditions in real or near-real time, and autonomously run entire production processes. Smart factories optimize efficiency and productivity by extending the capabilities of both manufacturing devices and people. By focusing on creating an agile, iterative production process through data collection, smart factories can aid decision-making processes with stronger evidence.

What is a smart factory?

The Smart Factory is a concept for expressing the end goal of digitization in manufacturing. It’s a popular phrase in the Industry 4.0 space. Automation has always been a part of the factory to some degree, and even high levels of automation are nothing new. However, the term “automation” suggests the performance of a single, discrete task or process. Historically, situations in which machines have made “decisions” have been automation-based and linear, such as opening a valve or turning a pump on and off based on a defined set of rules. Through the application of artificial intelligence (AI) and the increasing sophistication of cyber-physical systems that can combine physical machines and business processes, automation increasingly includes complex optimization decisions that humans typically make.

Finally—and perhaps most crucially—the term “smart factory” also suggests an integration of shop floor decisions and insights with the rest of the supply chain and broader enterprise through an interconnected IT/OT landscape. This can fundamentally change production processes and enhance relationships with suppliers and customers.

Through this description, it becomes clear that smart factories go beyond simple automation. The smart factory is a flexible system that can self-optimize performance across a broader network, self-adapt to and learn from new conditions in real or near-real time, and autonomously run entire production processes. Smart factories can operate within the four walls of the factory, but they can also connect to a global network of similar production systems, and even to the digital supply network more broadly.

Do smart factories help increase productivity?

Labor productivity is a major metric of economic output, and gains in productivity are important because, on a macro scale, labor productivity determines the standard of living of people, nations, and the world.

Deloitte research suggests that “smart factory” initiatives have yielded an average of 10-12% increase in labor productivity gains. Despite this success, a majority of manufacturers are still hesitant to move forward. On average, the industry only sees an increase of 0.7% in labor productivity each year. This represents a lack of investment in workforce performance and new technologies.

Early smart factory adopters reap twice as many benefits—reporting a 20% increase in labor productivity. Companies that were quick to bet on smart factory initiatives have seen unprecedented results. It’s time for manufacturers to learn from these early adopters, or “trailblazers,” and realize operational improvements of their own.

Conclusion

The promise of improved labor productivity is certainly enticing for manufacturing, as the industry sits in the midst of a labor shortage that is on the brink of becoming a drag on productivity. Technology can spur new levels of productivity throughout the factory as companies combine technologies (such as vision systems, harmonic sensors, and cobots with cognitive computing, machine learning, and autonomous capabilities). Each industrial revolution has seen this curve. Significant labor productivity gains manifest toward the end of the cycle, reflecting the cumulative impact of reaching a critical mass of technology adoption. Whether manufacturers are just starting on their smart factory journey or have already invested in it, there’s no doubt that smart factory initiatives will have a significant impact on manufacturing productivity.